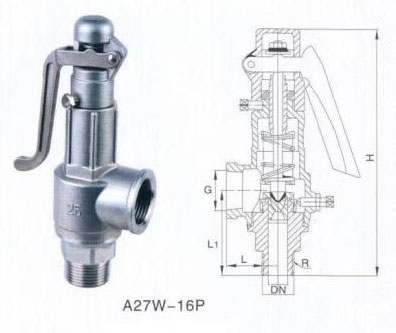

Specifications: DN15 to DN50

The pressure operating range can be adjusted by changing the spring

Connection method: welding, clamp, thread, flange

Working pressure: 16bar, 25bar, 40bar, 64bar

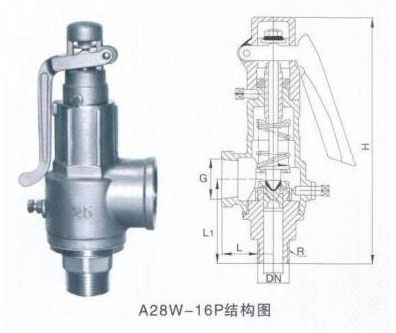

Specifications: DN15 to DN50

The pressure operating range can be adjusted by changing the spring

Connection method: welding, clamp, thread, flange

Working pressure: 16bar, 25bar, 40bar, 64bar

Working temperature: -10℃ to 120℃ (140℃ for short period or disinfection)

Material: 304/316L

Inner surface contact product: Ra≤0.8μm

External surface treatment: polishing

Seal: EPDM (ethylene propylene diene monomer), PTFE (polytetrafluoroethylene)

Starting pressure: 0.1bar - 10bar optional

Application

A27W/Y type is suitable for equipment and pipelines with water, air, steam and other media with working temperature ≤ 200℃. A27Y-P/R type is suitable for equipment or pipelines with corrosive media with working temperature < 200℃ as an overpressure protection device.

Main connection dimensions

|

Nominal diameter DN |

Size | |||||

| DN | do | R | L | L1 | G | ≈H | |

| 15 | 13 | 1/2" | 32 | 53 | 1/2" | 158 | |

| 20 | 18 | 3/4" | 35 | 60 | 3/4" | 170 | |

| 25 | 22 | 1" | 39 | 65 | 1" | 186 | |

| 32 | 28 | 1 1/4" | 46 | 80 | 1 1/4" | 202 | |

| 40 | 38 | 1 1/2" | 50 | 86 | 1 1/2" | 252 | |

| 50 | 38 | 2" | 55 | 95 | 2" | 286 | |

Application

A28W/Y type is suitable for equipment and pipelines with medium such as air, steam, water, ammonia hydrogen mixture and working temperature <200℃. A28W-P/R type is suitable for equipment or pipelines with corrosive medium with working temperature ≤200℃ as overpressure protection device.

Main connection dimensions

|

Nominal diameter DN |

Size | |||||

| DN | do | R | L | L1 | G | ≈H | |

| 15 | 13 | 1/2" | 35 | 60 | 3/4" | 171 | |

| 20 | 18 | 3/4" | 42 | 67 | 1" | 190 | |

| 25 | 22 | 1" | 48 | 73 | 1 1/4" | 197 | |

| 32 | 28 | 1 1/4" | 53 | 92 | 1 1/2" | 258 | |

| 40 | 38 | 1 1/2" | 53 | 101 | 2" | 264 | |

| 50 | 38 | 2" | 71 | 114 | 2 1/2" | 325 | |

Get A Quote !