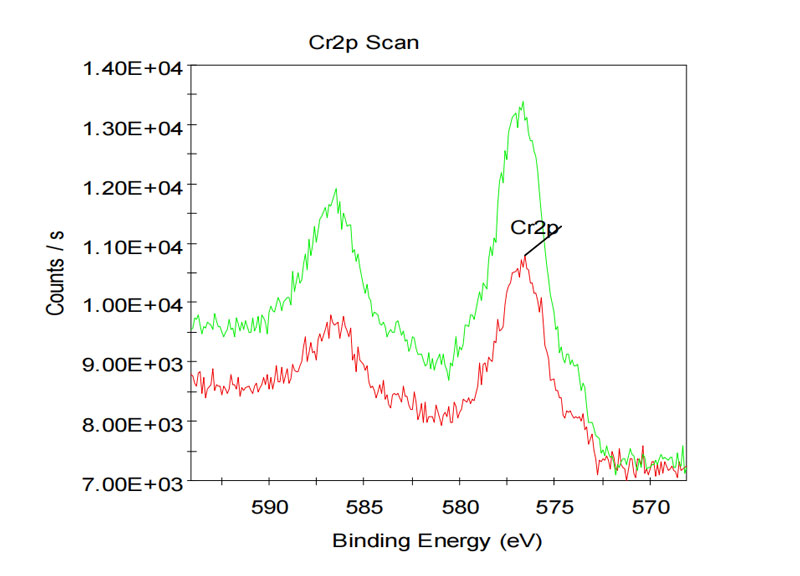

|

Attribute |

ASME BPE Recommendation |

Rexton Electronic polishing |

|

EP layer thi ckness |

<15A° |

<20A° |

|

CR/Fe ratio |

<1 |

<1.5 |

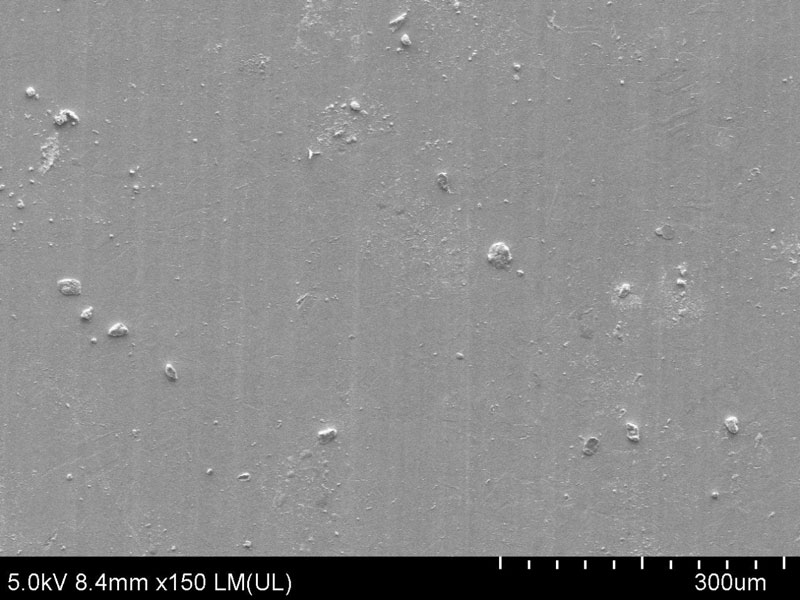

Rexton offers unparalleled surface quality

Surface treatment is deeply rooted in Rexton's tradition, and we constantly strive to enhance our processes through innovative production techniques and tailored solutions for our clients. Our focus is always on achieving higher standards of quality in everything we do.

Get A Quote !