Pneumatic Seat Valves

Diameter specification: 1 inch to 4 inches, DN25-DN100

Shell material: 304/316L

Seal: EPDM (ethylene propylene diene monomer), PTFE (polytetrafluoroethylene)

Diameter specification: 1 inch to 4 inches, DN25-DN100

Shell material: 304/316L

Seal: EPDM (ethylene propylene diene monomer), PTFE (polytetrafluoroethylene)

Working temperature: -10℃ to 100℃ (120℃ for short-term or disinfection)

Working pressure: 0.15-1.0Mpa

Control pressure: 0.3-0.8Mpa

Inner surface contact product: Ra≤0.8μm

External surface treatment: polishing

Control method: clean compressed air

Application areas: dairy, beverage, beer, pharmaceutical and other industries

Applicable media: gas, liquid, steam

Operation method: pneumatic

|

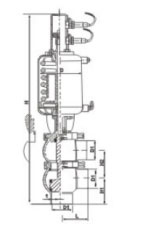

DIN | INCH | ||||||||||||||

| Size | H | H1 | H2 | T | D1 | D | L | Size | H | H1 | H2 | D1 | T | D | L | |

| DN25 | 360.5 | 51.5 | 53.5 | 1.5 | 28 | 87.5 | 49.3 | 1" | 360.5 | 51.5 | 53.5 | 25.4 | 1.5 | 87.5 | 49.3 | |

| DN32 | 490 | 64 | 68 | 1.5 | 34 | 87.5 | 61.8 | 1 1/4" | 490 | 6 | 68 | 31.8 | 1.5 | 87.5 | 61.8 | |

| DN40 | 490 | 64 | 68 | 1.5 | 40 | 87.5 | 61.8 | 1 1/2" | 490 | 64 | 68 | 38.1 | 1.5 | 87.5 | 61.8 | |

| DN50 | 530 | 69 | 75 | 1.5 | 52 | 115 | 72.5 | 2" | 530 | 69 | 75 | 50.8 | 1.5 | 115 | 72.5 | |

| DN65 | 556 | 76.35 | 91.5 | 2.0 | 70 | 115 | 79.5 | 2 1/2" | 556 | 76.5 | 91.5 | 63.5 | 2.0 | 115 | 79.5 | |

| DN80 | 620 | 98 | 112 | 2.0 | 85 | 133 | 98 | 3" | 600 | 90 | 105 | 76.2 | 2.0 | 133 | 90 | |

| DN100 | 660 | 111 | 132 | 2.0 | 104 | 173 | 111 | 3 1/2" | 615 | 98 | 112 | 89 | 2.0 | 133 | 98 | |

| 4" | 660 | 111 | 132 | 101.6 | 2.0 | 173 | 111 | |||||||||

|

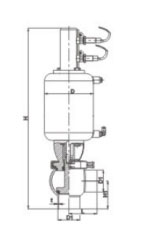

DIN | INCH | ||||||||||||

| Size | H | H1 | T | D1 | D | L | Size | H | H1 | D1 | T | D | L | |

| DN25 | 360 | 51.5 | 1.5 | 28 | 87.5 | 49.3 | 1" | 360 | 51.5 | 1.5 | 87.5 | 25.4 | 49.3 | |

| DN32 | 360 | 64 | 1.5 | 34 | 87.5 | 61.8 | 1 1/4" | 360 | 64 | 1.5 | 87.5 | 31.8 | 61.8 | |

| DN40 | 360 | 64 | 1.5 | 40 | 87.5 | 61.8 | 1 1/2" | 360 | 64 | 1.5 | 87.5 | 38.1 | 61.8 | |

| DN50 | 400 | 69 | 1.5 | 52 | 115 | 72.5 | 2" | 400 | 69 | 1.5 | 115 | 50.8 | 72.5 | |

| DN65 | 410 | 76.5 | 2.0 | 70 | 115 | 79.5 | 2 1/2" | 410 | 76.5 | 2.0 | 115 | 63.5 | 79.5 | |

| DN80 | 525 | 98 | 2.0 | 85 | 133 | 98 | 3" | 525 | 90 | 2.0 | 133 | 76.2 | 92 | |

| DN100 | 550 | 111 | 2.0 | 104 | 173 | 111 | 3 1/2" | 525 | 98 | 2.0 | 133 | 89 | 98 | |

| 4" | 550 | 111 | 173 | 101.6 | 111 | |||||||||

|

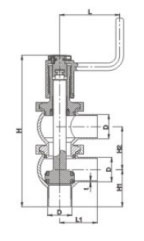

DIN | INCH | ||||||||||||||

| Size | H | H1 | H2 | t | D | L | L1 | Size | H | H1 | H2 | t | D | L | L1 | |

| DN25 | 242 | 51.5 | 53.5 | 1.5 | 28 | 80 | 49.3 | 1" | 242 | 51.5 | 53.5 | 1.5 | 25.4 | 80 | 51.5 | |

| DN32 | 260 | 64 | 68 | 1.5 | 34 | 80 | 61.8 | 1 1/4" | 248 | 64 | 68 | 1.5 | 31.8 | 80 | 64 | |

| DN40 | 260 | 64 | 68 | 1.5 | 40 | 80 | 61.8 | 1 1/2" | 248 | 64 | 68 | 1.5 | 38.1 | 80 | 64 | |

| DN50 | 276 | 69 | 75 | 1.5 | 52 | 80 | 72.5 | 2" | 276 | 69 | 75 | 1.5 | 50.8 | 80 | 69 | |

| DN65 | 296.5 | 76.5 | 91.5 | 2.0 | 70 | 90 | 79.5 | 2 1/2" | 296.5 | 76.5 | 91.5 | 2.0 | 63.5 | 90 | 76.5 | |

| DN80 | 340 | 98 | 112 | 2.0 | 85 | 90 | 98 | 3" | 340 | 90 | 105 | 2.0 | 76.2 | 90 | 90 | |

| DN100 | 405 | 111 | 132 | 2.0 | 104 | 100 | 111 | 3 1/2" | 348 | 98 | 112 | 2.0 | 89 | 90 | 98 | |

| 4" | 405 | 111 | 132 | 2.0 | 101.6 | 100 | 111 | |||||||||

|

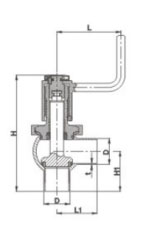

DIN | INCH | ||||||||||||

| Size | H | H1 | t | D | L | L1 | Size | H | H1 | t | D | L | L1 | |

| DN25 | 173 | 51.5 | 1.5 | 28 | 80 | 49.3 | 1" | 173 | 51.5 | 1.5 | 25.4 | 80 | 49.3 | |

| DN32 | 173 | 64 | 1.5 | 34 | 80 | 61.8 | 1 1/4" | 173 | 64 | 1.5 | 31.8 | 80 | 61.8 | |

| DN40 | 173 | 64 | 1.5 | 40 | 80 | 61.8 | 1 1/2" | 173 | 64 | 1.5 | 38.1 | 80 | 61.8 | |

| DN50 | 190 | 69 | 1.5 | 52 | 80 | 72.5 | 2" | 190 | 69 | 1.5 | 50.8 | 80 | 72.5 | |

| DN65 | 212 | 76.5 | 2.0 | 70 | 90 | 79.5 | 2 1/2" | 212 | 76.5 | 2.0 | 63.5 | 90 | 79.5 | |

| DN80 | 240 | 98 | 2.0 | 85 | 90 | 98 | 3" | 240 | 90 | 2.0 | 76.2 | 90 | 90 | |

| DN100 | 254 | 111 | 2.0 | 104 | 100 | 111 | 3 1/2" | 240 | 98 | 2.0 | 89 | 90 | 80 | |

| 4" | 254 | 111 | 2.0 | 101.6 | 100 | 111 | ||||||||

Get A Quote !